Your vehicle’s wheels are one of the most important parts of your car as these get you to your destination safely – with efficiency and under any condition.

Well-maintained tires are not just based on wheel alignments but also on optimum tire pressure and tread depths. Beyond the surface of the wheel assembly lies perhaps its most crucial aspect, the wheel bearings.

There are many causes of bearing failure. These can include excessive vehicle loads and road hazards such as potholes or any other forms of obstruction. Premature bearing damage can also be attributed to poor car handling and inexperienced disassembly or installation.

Being able to identify the main causes of bearing failure can assist in understanding when your vehicle needs new wheel bearings. According to top bearing supplier companies, these are the five clues for replacement.

Table of Contents

1. Unfamiliar noise

One of the first indicators that you may need new bearings is an unusual sound coming from your wheels. While this may vary, the most common will be rumbling or cyclic noises.

To confirm if the unfamiliar noises are indeed attributed to your wheel bearings, do a test by operating your car at different speeds. If there is a variation of sounds, you may start contacting your mechanic for wheel bearings repair.

2. Abnormal wheel vibration

Functioning wheel bearings allow your vehicle to maneuver in the manner that they should. Well-maintained wheel bearings promote efficient rotation.

Poor functioning wheel bearings meanwhile will make your vehicle feel less responsive and less precise with a tendency of having lesser steering control. On the other hand, abnormal wheel vibration can also be associated with a myriad of drivetrain issues. Worn tires, damaged suspension components or even a chassis misalignment could be indicating factors.

The exact issues though can be determined by a licensed mechanic who can accurately assess the main cause and solution.

3. Poor steering wheel conditions

Do you feel vibrations or wobbling through your steering wheel while driving?

If obvious vibration or wobble can be felt through your steering wheel, examine your wheel bearings as corrosion can cause them to loosen. This looseness effect will transfer to the steering wheel which will cause it to pull abnormally.

Your steering wheel can also indicate which wheel bearings are failing. When turning slightly left or right, listen carefully and identify which side is the source of noise. This will indicate the defective side.

4. Uneven brake and tire wear

As indicated above, wheel bearings that are improperly installed can make wheels wobble, causing them to be excessively worn out. A simple visual inspection of your tires will tell you which bearing has premature failure.

If the vehicle has recently gone through its routine tire rotations and wheel alignments tests, then it’s time too to have your wheel bearings checked.

Wheel bearings that become loose can also attribute to uneven wear in your brake pads. When brakes are applied, excessive force can cause them to pulsate and pull. Like wheels, brake wear is a visual inspection process.

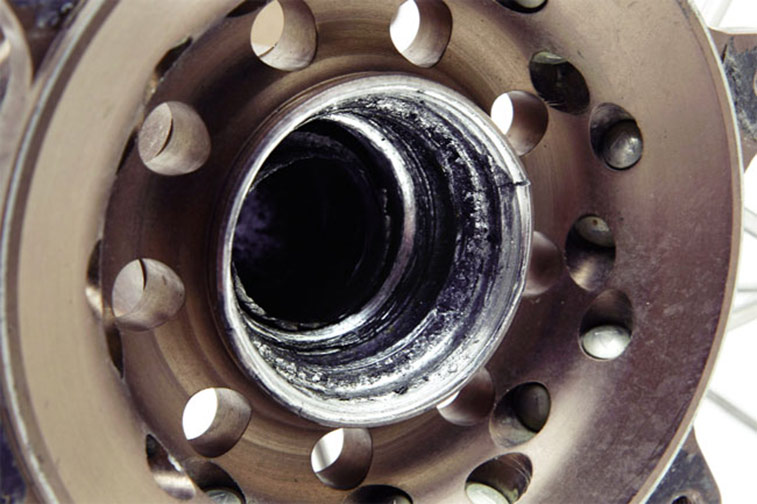

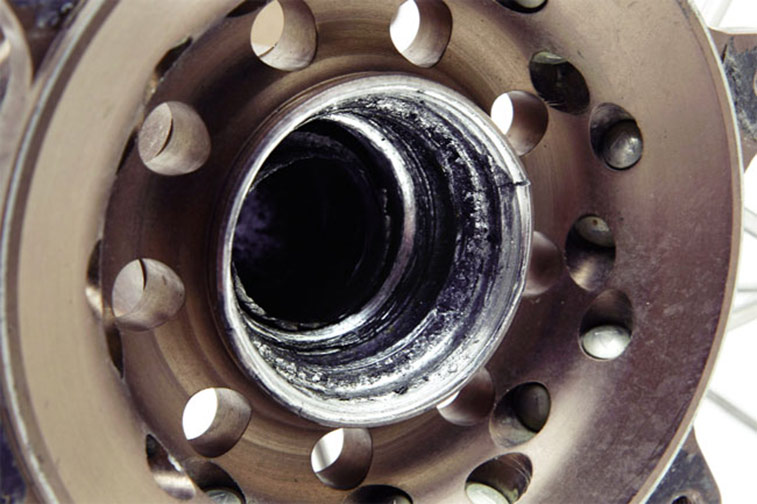

5. Broken oil seals

While broken oil seals are lesser known symptoms of poor wheel bearing performance, they are nonetheless very important. Normally firmly fitted in the wheel assembly, these ensure wheel bearing protection against debris or contaminants.

Wheel bearings are normally sealed units with tremendous amount of grease that provides proper lubrication for a smoother run and longer service life. Thus, broken or loose ones will cause grease leakage, leading to breakdown of your wheel bearings and other spare part components.

The increased heat or temperature in wheel bearings due to inadequate bearing grease or improper lubrication can lead to catastrophic failure.

Finally, regular maintenance of wheel bearings should not be overlooked as it ensures efficient vehicle performance which in the long run will reduce emergency repair costs. Most significantly, it is advisable that you get your wheel bearings fixed by a licensed mechanic who has the appropriate tools and know-how to repair your wheel bearings.

AUTHOR BIO

Hassanein Alwan is the Marketing Director of Mineral Circles Bearings with more than 10 years’ experience in the bearing industry’s technical support division, strategic business development consultancy as well as sales and marketing.

With a degree of Master of Science in Engineering from KTH Royal Institute of Technology and an International Diploma in Business from the University of Cambridge, he started his career in Sweden as a Machine Safety engineer for Gröna Lund and as SAAB Aerosystems’ Aeronautical engineer. Today, he serves as a member of the Know Your Market Committee after joining EPTDA in 2013.